Innovations in Sustainable 3D Printing: The Future of Eco-Friendly Manufacturing

Introduction

As the world grapples with environmental challenges, industries are seeking ways to reduce waste, lower carbon footprints, and create more sustainable production methods. One of the most promising advancements in manufacturing is sustainable 3D printing, which offers energy-efficient, waste-reducing, and eco-friendly alternatives to traditional production techniques.

From biodegradable materials to closed-loop recycling systems, the innovations in green 3D printing are revolutionizing industries like automotive, aerospace, healthcare, and consumer goods. This article explores the latest breakthroughs in sustainable 3D printing technologies, the materials driving change, and the impact on global sustainability efforts.

“The greatest threat to our planet is the belief that someone else will save it.” – Robert Swan

In the same way, embracing sustainable 3D printing today ensures a cleaner, greener, and more innovative future.

1. The Environmental Challenges of Traditional Manufacturing

Before diving into sustainable 3D printing innovations, it’s crucial to understand the environmental impact of traditional manufacturing:

High Material Waste

🔹 Traditional subtractive manufacturing techniques, such as CNC machining, cut away excess material, leading to significant waste.

🔹 In industries like automotive and aerospace, up to 70% of raw material is wasted in machining processes.

Excessive Energy Consumption

🔹 Manufacturing processes often require high temperatures, pressure, and complex machinery, increasing energy consumption.

🔹 Steel and aluminum production are among the most energy-intensive industrial processes, contributing heavily to CO₂ emissions.

Toxic Byproducts and Pollution

🔹 Conventional manufacturing releases harmful chemicals, greenhouse gases, and industrial waste into the environment.

🔹 Factories are major contributors to air and water pollution, affecting both human health and ecosystems.

Supply Chain Inefficiencies

🔹 Traditional manufacturing relies on mass production and long supply chains, increasing carbon footprints through transportation and logistics emissions.

💡 Solution: Sustainable 3D printing technologies are addressing these challenges by introducing eco-friendly materials, efficient production techniques, and circular economy principles.

2. Sustainable 3D Printing Innovations

A. Eco-Friendly & Recycled Filaments

One of the biggest breakthroughs in sustainable 3D printing is the development of eco-friendly materials:

Biodegradable Polymers (PLA & PHA)

✔️ Polylactic Acid (PLA) – A biodegradable filament derived from cornstarch or sugarcane, commonly used in consumer and medical 3D printing.

✔️ Polyhydroxyalkanoates (PHA) – A bioplastic made from bacteria, offering better biodegradability than PLA.

📌 Impact: These filaments decompose naturally, reducing plastic waste and promoting sustainable disposal.

Recycled PET & Ocean Plastic Filaments

✔️ rPET (Recycled Polyethylene Terephthalate) – Made from recycled plastic bottles, reducing landfill waste.

✔️ Ocean Plastic Filament – Created from ocean-recovered plastics, helping clean marine ecosystems while providing sustainable printing materials.

📌 Impact: Prevents new plastic production and helps combat ocean pollution.

Wood & Bamboo-Based Filaments

✔️ Wood PLA – A blend of recycled wood fibers and PLA, creating a natural, biodegradable material.

✔️ Bamboo Filament – Lightweight, sustainable, and suitable for furniture, decorative pieces, and biodegradable products.

📌 Impact: Offers a renewable alternative to plastic, reducing reliance on fossil fuel-based materials.

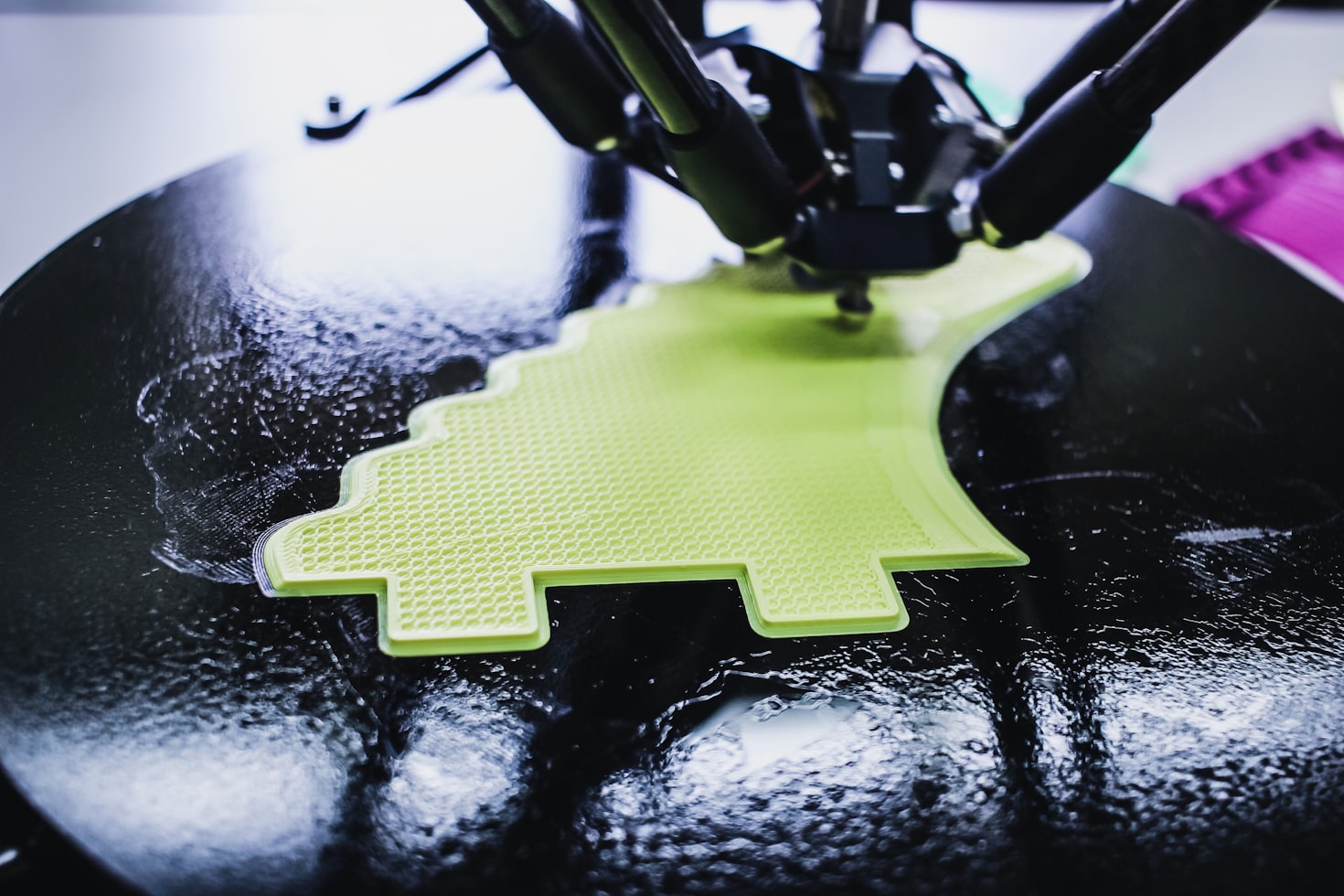

B. Closed-Loop Recycling Systems

A major innovation in sustainable 3D printing is the development of closed-loop recycling, where old prints and waste materials are repurposed into new filament.

🔹 Filament Recyclers – Devices like Filabot and ProtoCycler grind used plastic parts into new filament, enabling a circular manufacturing process.

🔹 In-House Recycling – Companies like Prusa Research are implementing on-site recycling solutions to reduce filament waste.

🔹 Zero-Waste Labs – Universities and research institutions are exploring ways to integrate 3D printing waste into new construction materials.

📌 Impact: Eliminates single-use plastic, reduces industrial waste, and promotes resource efficiency.

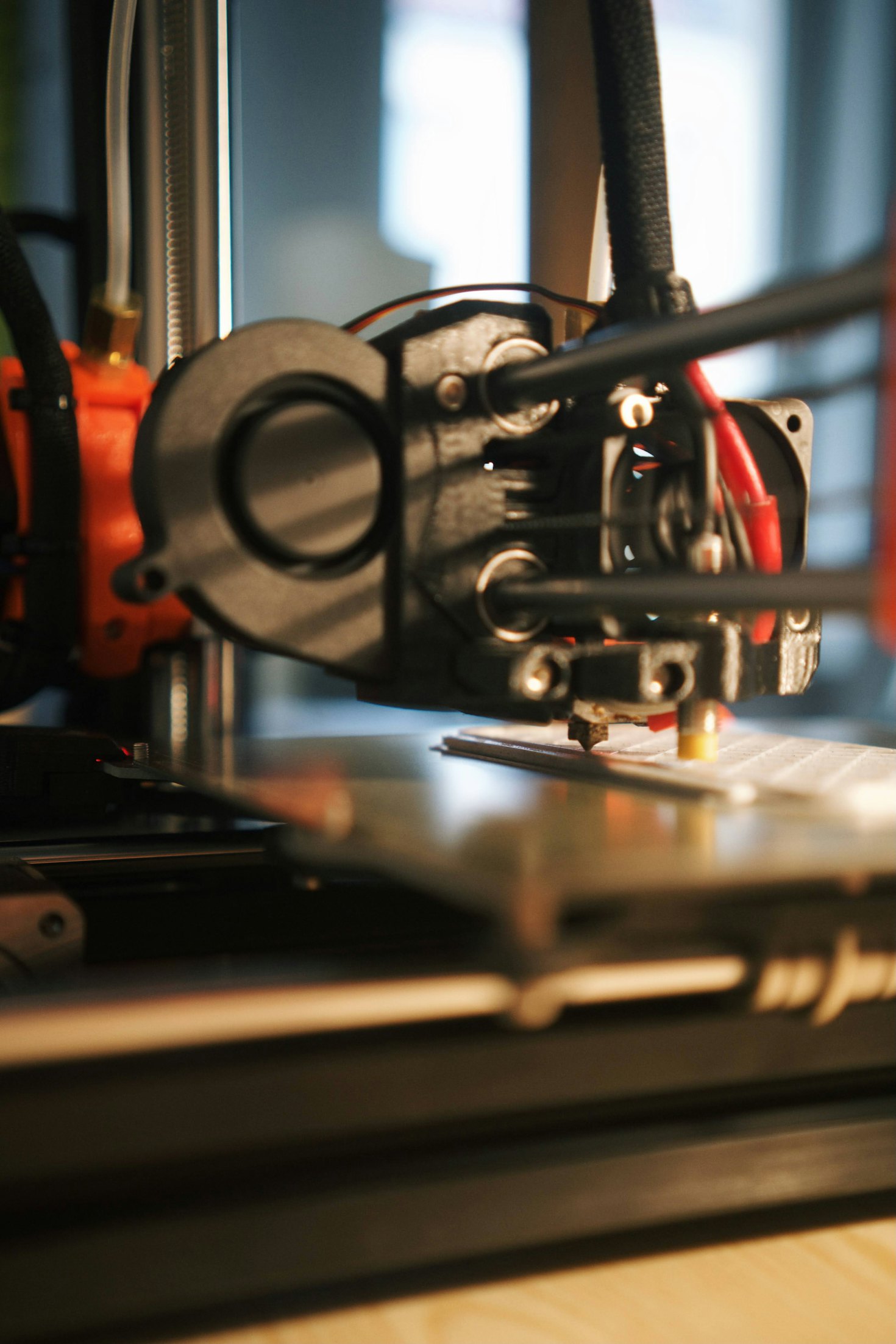

C. Energy-Efficient Printing Technologies

Unlike traditional manufacturing, which consumes excessive energy, 3D printing requires significantly less power.

✔️ Cold Sintering Process (CSP) – Reduces energy consumption in ceramic and metal 3D printing by up to 80%.

✔️ Solar-Powered 3D Printers – Innovations like Solar Sinter use solar energy to 3D print objects using desert sand, reducing reliance on fossil fuels.

✔️ Low-Temperature Printing – Some biodegradable filaments now work at lower melting points, reducing overall power consumption.

📌 Impact: Lowers energy costs and reduces carbon footprints for large-scale production.

D. 3D Printing for Sustainable Construction

The construction industry is adopting sustainable 3D printing with groundbreaking solutions:

✔️ 3D Printed Homes with Recycled Concrete – Companies like ICON and COBOD use recycled cement and sustainable binders to construct energy-efficient housing.

✔️ Bio-Based Construction Materials – Hempcrete and mycelium-based biodegradable building materials are emerging as eco-friendly alternatives.

✔️ On-Site 3D Printing – Reduces transportation emissions by producing building materials at the construction site.

📌 Impact: Reduces construction waste, speeds up sustainable housing projects, and lowers CO₂ emissions.

3. The Future of Sustainable 3D Printing

🌍 Circular Economy Models – Moving toward fully recyclable 3D printing systems where zero waste is generated.

🌱 Bioprinting for Sustainability – Researchers are exploring bioprinting plant-based alternatives for biodegradable packaging.

🔋 3D Printing with Renewable Energy – More solar, wind, and hydro-powered 3D printers will emerge, further reducing energy use.

🚀 Space Sustainability – NASA is testing 3D printing using lunar and Martian dust, reducing the need for raw material transport.

Conclusion: The Role of 3D Printing in a Sustainable Future

Sustainable 3D printing is more than just a trend—it is a necessity for the future of manufacturing. By minimizing waste, lowering energy consumption, and utilizing biodegradable materials, 3D printing is paving the way for a cleaner, greener world.

Key Takeaways:

✔️ Eco-friendly materials like PLA, PHA, and recycled filaments reduce plastic pollution.

✔️ Closed-loop recycling systems enable waste-free manufacturing.

✔️ Energy-efficient printing technologies lower carbon footprints.

✔️ 3D-printed homes and sustainable construction materials promote green building practices.

✔️ Future innovations will drive 3D printing toward a fully sustainable circular economy.

🚀 It’s time to embrace sustainable 3D printing and revolutionize the way we manufacture, one eco-friendly layer at a time!

🔗 Learn More at: 3D Printing Coin (3DPC)

Leave a Reply